CE Certification Femoral Interlocking Nail Service – Pelvis and Hip Joint Locking Plate System – AND

CE Certification Femoral Interlocking Nail Service – Pelvis and Hip Joint Locking Plate System – AND Detail:

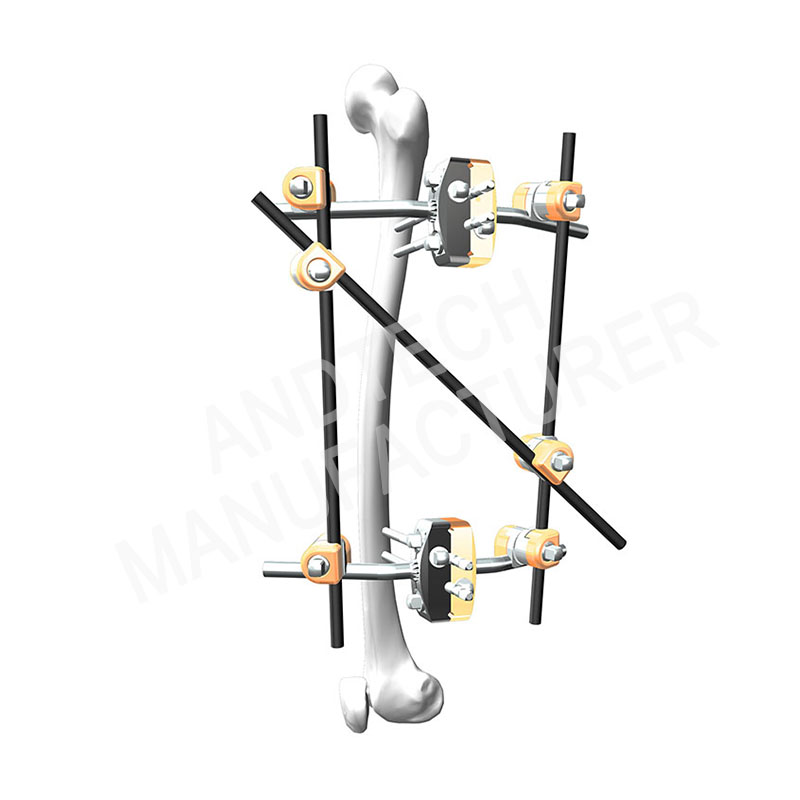

pelvis locking plate

Code: 251605

Width: 10mm

Thickness: 3.2mm

Material: TA3

Screw Size:

HC3.5, HA3.5, HB4.0

Coaxial hole design

● The same hole can be used for the locking screw and normal screw

● Low-profile design can reduce the soft tissue irritation

● Reconstruction design can be easy bending in the operation

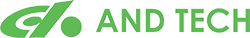

Proximal Femoral locking Plate IV

Code: 251718

Width: 20mm

Thickness: 5.9mm

Material: TA3

Screw Size: Head: HC6.5 (hollow)

Body: HC5.0, HA4.5, HB6.5

● Excellent anatomic pre-shaped design, no need bending in the operation.

● The Proximal end with 6pcs fixed holes, 5pcs screw to support the femoral neck and head, one screw is aim to femoral calcar, more suitable for proximal femoral biomechanics.

● Thicker design for the stress concentration plate part to reduce the broken risk.

● Proximal K-wire hole is convenient for temporary fixation and provide reference point for the plate placement.

Meical Tips

The hip joint is composed of the femoral head and the acetabulum facing each other, and belongs to the club and socket joint. Only the lunar surface of the acetabulum is covered with articular cartilage, and the acetabular fossa is full of fat, also known as Haversian glands, which can be squeezed out or inhaled with the increase or decrease of intra-articular pressure to maintain the balance of intra-articular pressure.

At the edge of the acetabulum there is a glenoid rim attached. Deepen the depth of the joint socket. There is a transverse acetabular ligament on the acetabular notch, and it forms a hole with the notch, through which nerves, blood vessels, etc. pass.

Pelvic fracture is a serious trauma, accounting for 1% to 3% of the total number of fractures. It is mostly caused by high-energy trauma. More than half are accompanied by comorbidities or multiple injuries, and the disability rate is as high as 50% to 60%. The most serious are traumatic hemorrhagic shock and combined injury of pelvic organs. Improper treatment has a high mortality rate of 10.2%. According to statistics, 50%~60% of pelvic fractures are caused by car accidents, 10%~20% are caused by pedestrians being hit, 10%~20% are motorcycle injuries, 8%~10% are falling from height, 3% ~6% are severe crush injuries.

Violent direct blows, falls from heights, vehicle impacts, crushing, etc. can all cause femoral fractures. When a femur fracture occurs, the lower limbs cannot move, the fracture site is severely swollen and painful, and deformities such as distortion or angulation may occur, and sometimes the length of the lower limbs may be shortened. If there is an open wound at the same time, the condition will be more serious, and the patient will often experience shock. The femur is the largest bone in the body. If it is not treated in time after the fracture, it can cause severe complications such as hemorrhage and nerve damage. Therefore, it must be fixed and bandaged quickly and correctly, and then sent to the hospital for treatment immediately.

Intracapsular fractures of the femoral neck are more common in elderly patients, but less in young people due to bone quality. If not properly treated, femoral neck fractures can lead to disability, and in severe cases can cause death. At present, there are many treatment strategies for femoral neck fractures, and the choice of treatment plan depends on the patient’s age, mobility, medical complications and other related conditions.

Product detail pictures:

Related Product Guide:

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for CE Certification Femoral Interlocking Nail Service – Pelvis and Hip Joint Locking Plate System – AND , The product will supply to all over the world, such as: Venezuela, Ukraine, Cape Town, Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact me. We are looking forward to forming successful business relationship with new clients around the world.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!